Products

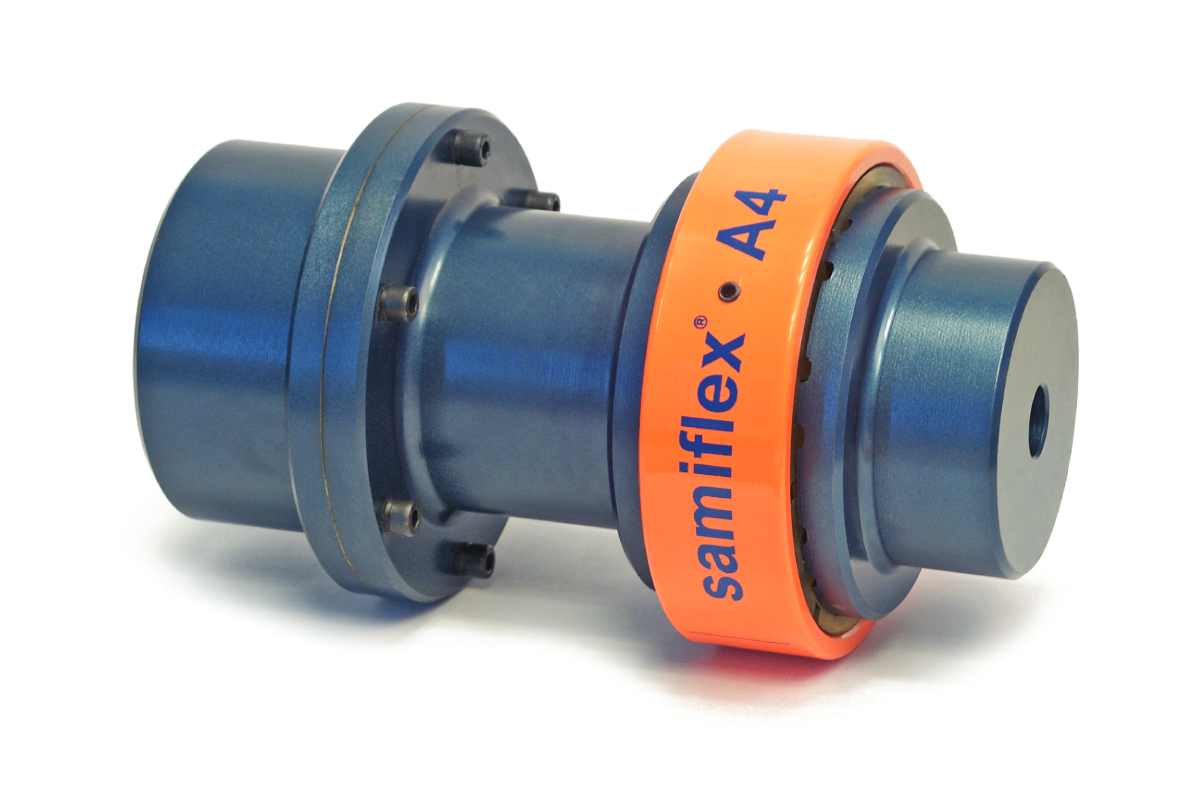

Samiflex® Couplings

Our own flexible coupling, produced in all versions and designed to meet the most demanding requirements of modern industry. It is a widely recognized flexible coupling known for its durability, simplicity, and performance.

They allow the elastic insert to be mounted and removed without the need to move either the motor or the machine.

They enable fast, safe, and highly precise mounting and dismounting between the shaft and the rotating component. Available from A1 to A7.

Brake pulley coupling, PF Type.

Flange-shaft adaptation coupling, EB SAE Type.

Brake disc coupling, DF Type.

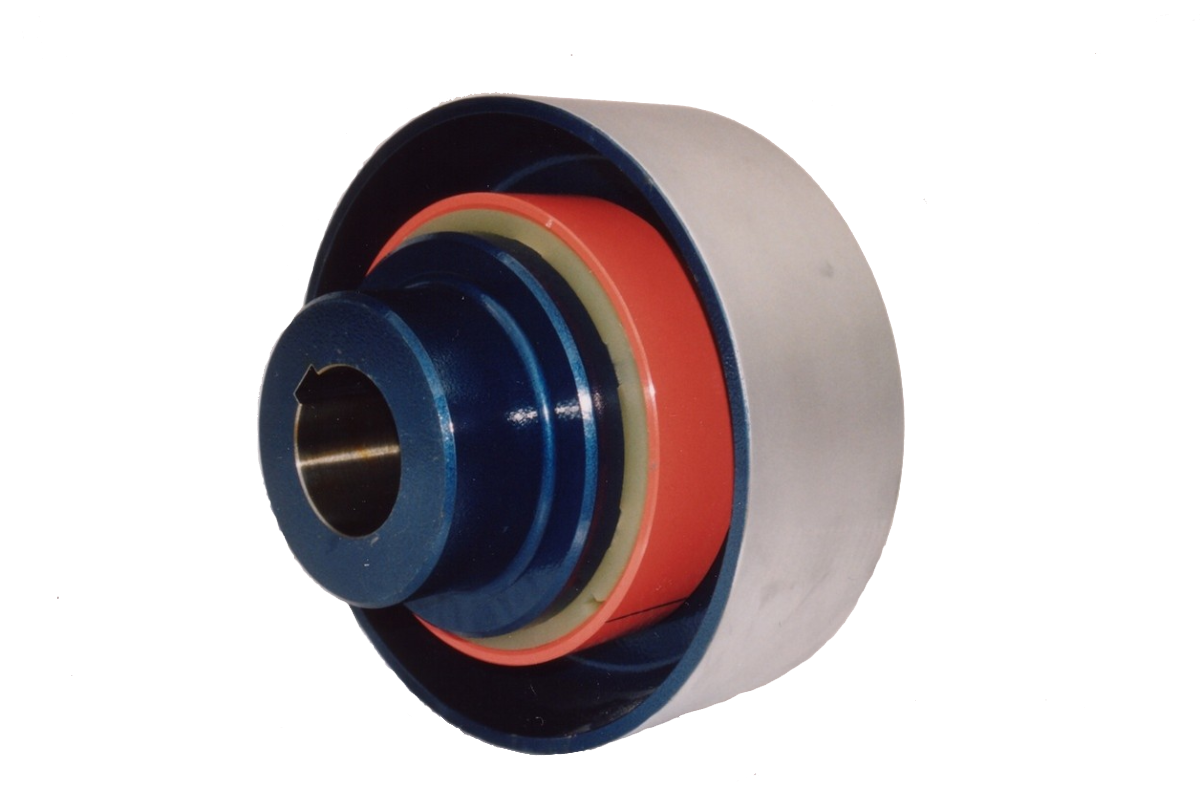

Elastic insert for Samiflex couplings, capable of withstanding temperatures from -40º up to 140º.

Other solutions

Samiflex® is our flagship brand, but we can also offer other couplings.

Jaw Flex couplings

Its three-piece design is 100% interchangeable with the vast majority of global manufacturers, ensuring low-cost replacement parts that are always available.

Unlike Samiflex® couplings, the star-type design operates under compression. The metallic jaws compress the elastomer, allowing higher torque transmission in a more compact size.

StS couplings

We offer the following couplings from the StS Coupling GmbH brand:

- Elastomer servo couplings.

- Hysteresis magnetic clutches.

- Torque limiters.

Special projects

End-to-end projects for large mining operations, seaports, and any custom development that requires specialized engineering.

Customized couplings for conveyor belts operating under extreme conditions.

Couplings for port applications

OEM manufacturing

Our quality and precision applied to your projects. Here are some examples — but tell us, what do you need?

Elastic couplings

Tell us what you need and we’ll make it happen. Your dimensions, your colors — everything is possible.

Flexible couplings with spacer

You imagine it. We make it happen.

Cast iron foundry

We can produce all types of custom cast-iron components, such as wheels, valve bodies, and plates.

- Maximum part size: 600 mm x 700 mm x 350 mm.

- Maximum part weight: up to 600 kg (with current equipment) and up to 1,000 kg (with previous specifications).

- Custom mold development available upon customer request.

Centrifugal pump impeller